Contact: Yujian Gang

Mobile: 18013270118

QQ: 2290618142

E-mail: 2290618142@qq.com

Tel: 0512-55101929

Address: Jiangsu province Yushan city Kunshan town Foxconn No. 1183 Road (highway 339) and Industrial Park

Air compressor waste heat recovery system

First, the compressed air system overview

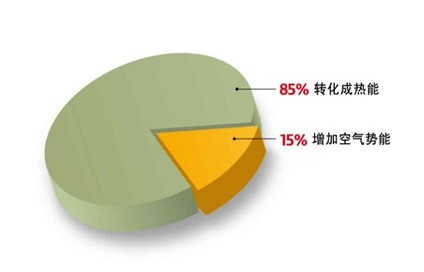

According to the US Department of Energy statistics. When the compressor is in operation, the electricity used to increase the energy consumed by the air is only a small part of the total power consumption of 15%, about 85% of the electricity into heat, through the air-cooled or water-cooled way to in the air.

Laissez-faire these "excess" heat emissions into the air, not only affects the environment, creating a "hot" pollution, in fact, for these wasted heat, the use of air compressor heat recovery technology, which seem superfluous heat, of which 80% Can be recycled!

Second, the compressed air system heat recovery energy-saving solutions

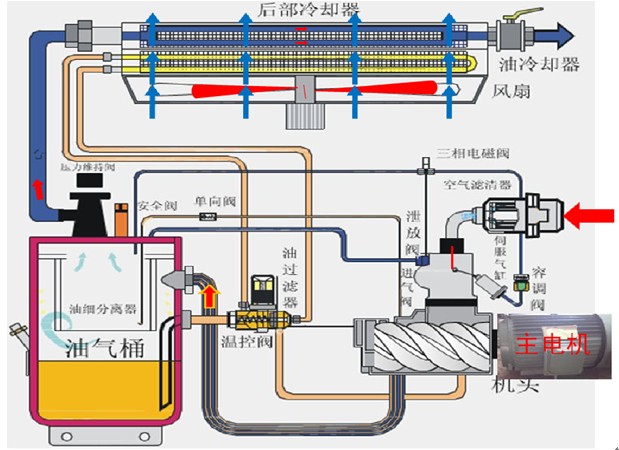

The heat recovery system is installed outside the air compressor system, through the tubing and connecting parts connected with the air compressor, and then through the transformation of the air compressor to meet:

Ø the normal working oil temperature of the compressor;

Ø does not destroy the normal work of the compressor;

Ø clean appearance, safe and reliable system to ensure the stable operation of the system;

Ø waste heat utilization, energy saving and environmental protection, reduce greenhouse gas emissions, good economic and social benefits;

Ø Safe and quality guaranteed.

Third, the technical feasibility analysis:

Air compressor operation of the waste heat, if not exchanged, can cause the motor high temperature and high temperature, not only affect the air compressor life, but also affect the quality of compressed air; such as by the cooling system will be heat emissions, not only a waste Energy, but also cause thermal pollution.

![]() Application project

Application project

| Application project |

Overview of the status quo |

Transformation target |

Remarks |

|

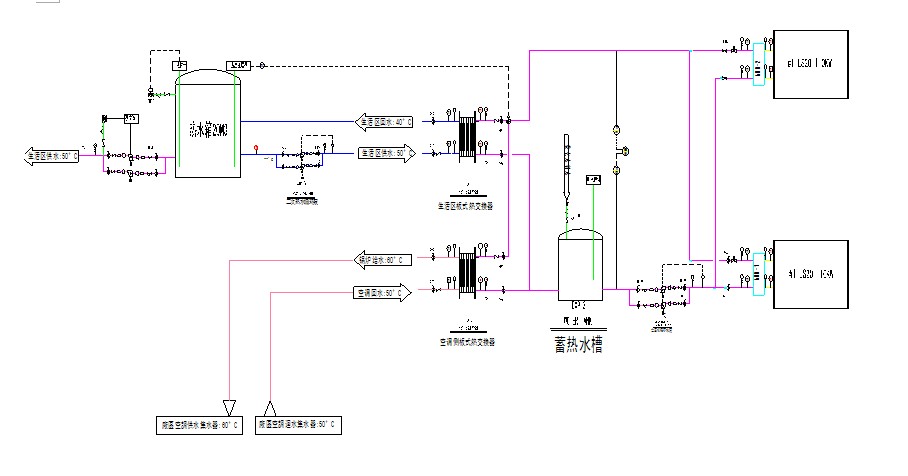

Life hot water \ air conditioning hot water |

Air compressor waste heat heating hot water storage heat storage tank for air conditioning heating and living area 400 people use bath |

More than water for air conditioning systems |

Description: Recycling air compressor running to generate heat to 70 ℃ hot water stored in the storage tank to meet the living area hot water secondary heat transfer 55 ℃ water supply temperature requirements; secondary air conditioning with hot water temperature through the ratio of three (PID temperature adjustment) control at 45 ℃; above the main address to the following aspects of the heat demand: hot water \ air conditioning hot water

![]() Feasibility analysis based on:

Feasibility analysis based on:

1. 1 ton of water per 1 ℃, the required calories of 1,000kcal

2. Living area bath hot water supply temperature 55 ℃

3. Summer replenishment temperature 25 ℃, winter 10 ℃, spring 15 ℃, the average temperature of 15 ℃

4. Electric power calorific value: 860 kcal, electricity unit price 0.8 yuan / KW.H

![]() analyze data:

analyze data:

Air compressor can be recovered daily heat Q:

Q = 150KW (air compressor power) × 50% (recovery efficiency) × 24 (hours) = 1800KW

Recycled daily heat equivalent to about 1440 yuan.

Air compressor daily hot water production G:

G = 1800 KW x 860 kCal / 1000 kCal / (55-15) C = 38.7 T

Air compressor to provide hot water per day Number of people available for bathing:

80L / person = 38.7T / 0.08T≈484 people 80L equivalent to barrels of purified water 4 barrels

Air compressor waste heat minus the daily hot water demand, if the surplus calorific value for air conditioning or other purposes.

Energy efficiency analysis: (with all the heat is calculated)

1440 yuan × 30 days = 43300 / month

Air compressor daily recovery of heat can save 43.3 million per month

Fourth, the control system description

![]() Using two control methods:

Using two control methods:

(1) manual control that is through the manual operation button control circuit motor start and stop, easy to detect

Maintenance

(2) the use of PLC controller to monitor and control the entire control system to monitor the system a secondary side of the main operating parameters, can provide operating status, fault alarm function. The pump is running automatic and manual options, in the automatic operation state always maintain a pump in the running state; automatic liquid level water supply and water supply side of the original system automatically water function. Effectively prevent the system due to fault caused by bath side of the water, better meet the heat needs.

Fifth, the project example:

Copyright @ Kunshan Izumi Industrial Co. Ltd. Browse: 257199 Technical support: Lucheng Information Port

Jiangsu address: No. 1183, Foxconn Road, Yushan Town, Jiangsu, Kunshan (No. 339) Tel: 0512-55101929

Email: 2290618142@qq.com