Contact: Yujian Gang

Mobile: 18013270118

QQ: 2290618142

E-mail: 2290618142@qq.com

Tel: 0512-55101929

Address: Jiangsu province Yushan city Kunshan town Foxconn No. 1183 Road (highway 339) and Industrial Park

China's current total installed capacity of the motor accounted for more than 70% of the current total electricity consumption, of which nearly 70% of the motor drag the load is the fan, pumps, compressors, etc., of which nearly 70% of the motor for speed , That is about 200 million kilowatts of the motor in a state of wasteful operation. In contrast, China's GNP energy consumption is made

Up to 4-8 times the country, the energy utilization rate is less than 70% of the developed countries, and coal, oil and other primary energy and increasingly tense, energy issues have become China's largest strategic issues, both from the current business efficiency and future The energy of the links are very important.

Our company combined with the current motor design margin is too large, the use of frequent changes in operating conditions, the use of frequency control, fixed frequency transfer, harmonic control, power factor improvement and soft start and other technical means to design a new generation of power saving device , Effectively improve the efficiency of the motor, save energy, reduce equipment maintenance costs.

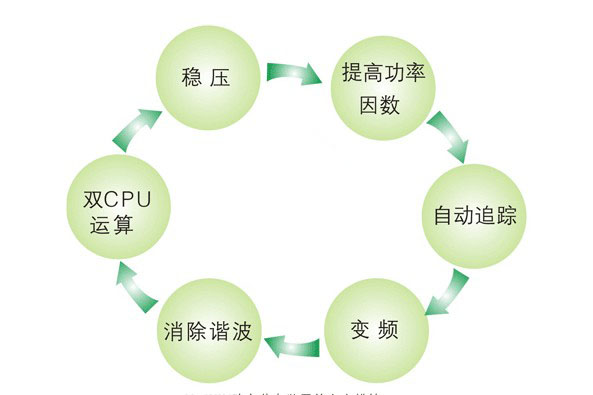

Power-saving device is designed for all types of motor-driven power-saving devices, the power-saving principle mainly: frequency control, fixed frequency power, harmonic processing, dual CPU operation, regulation, power improvement, automatic tracking.

1, the hydraulic system of the pump power consumption;

2, the power consumption of the heater;

3, the circulating cooling water pump power consumption.

Which the hydraulic pump power consumption of the entire injection molding machine power consumption of more than 80%, so reduce its power consumption is the key to energy-saving injection molding machine. Injection molding machine in the mold, clamping, injection, cooling and other stages of the required pressure and flow

Are changing, when the injection molding machine oil demand changes, by the oil pump outlet in the relief valve to adjust the load pressure and flow, while the motor output power unchanged, resulting in energy waste.

At the same time, the motor in low load state work: motor efficiency and power factor is very low, reactive power consumption is great. Taken together, the traditional injection molding machine hydraulic system there is a serious waste of energy.

Injection molding machine dedicated energy-saving device can automatically according to the injection molding machine's own working pressure and flow signal, real-time analysis and calculation, synchronous control of the energy-saving device output frequency and voltage, so as to accurately adjust the pump

Speed, so that the actual pump fuel supply and injection molding machine working flow demand is consistent. In order to ensure the stability of the system under the premise of the work, the original injection molding machine to control the phenomenon of the minimum state, thus substantial savings

Can consume.

Example: The following figure is a comparison of the measured power consumption curve in the energy saving state and in the normal state when the power saving device is applied to a Yilida E160 machine (motor power 18.5KW).

Second, the characteristics of injection molding machine energy-saving devices

|

1, the general conditions of energy-saving rate of up to 30% -50%; under normal circumstances, 6-12 months to recover all the investment; |

Copyright @ Kunshan Izumi Industrial Co. Ltd. Browse: 257199 Technical support: Lucheng Information Port

Jiangsu address: No. 1183, Foxconn Road, Yushan Town, Jiangsu, Kunshan (No. 339) Tel: 0512-55101929

Email: 2290618142@qq.com